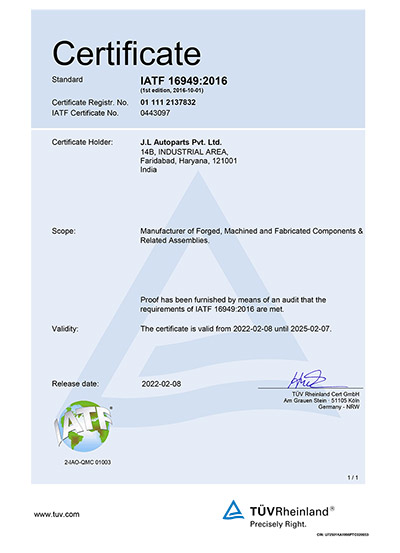

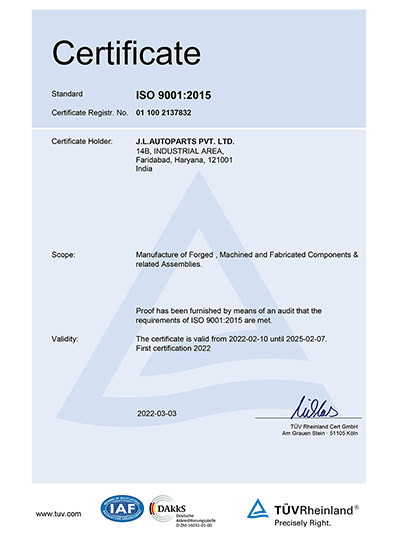

The ISO 9001:2015 and IATF 16949:2016 certified companies. JL Auto Parts Pvt. Ltd. and A D Precision Forgings Pvt. Ltd. adhere to a well-defined quality policy to ensure the durability and efficiency of the products. Fully furnished quality labs boast gadgets from all over the world, including Spectrometer, Microscopic Image Analyzer, Weld Penetration Microscope, Gear Lead Profile Tester, CMM or Co-ordinate Measuring Machine, Roundness Tester, Contracer, Digital Hardness Tester, Metallurgical Microscope, Profile Projector, Surface Finish Tester, Universal Testing Machine, Eddy Current Sorter, Optical Sorting Inspection System, MPI Machine, Salt Spray Test Machine, Digital Height Gauge and Micro Vickers Hardness Tester. At each and every stage of manufacturing, well-trained quality assurance engineers conduct a series of testing and inspection procedures conforming the quality guaranty of parts. Using POKA-YOKE concept, they eliminate the possibility of even the minutest defects. DOL Delivery System with 100% flawless deliveries has been key to cementing relations with customers through ERP System and Customer Delivery Portal.